What Is a Process Challenge Device?

A process challenge device (PCD) is a tool used in laboratories and healthcare facilities that helps technicians determine the efficacy of their sterilization processes. These devices are specifically designed to simulate highly complicated loads and are placed within sterilizing units during validation testing to challenge their ability. This way, if a unit successfully sterilizes the test pack, technicians can safely assume that it is also capable of achieving 100% sterilization during every-day use, as these loads are typically much easier for the sterilizing agent to penetrate.

PCDs are used as part of the validation process for all types of sterilizers — steam, ethylene oxide, dry heat, vaporized hydrogen peroxide, and ozone.

Process Challenge Device Types

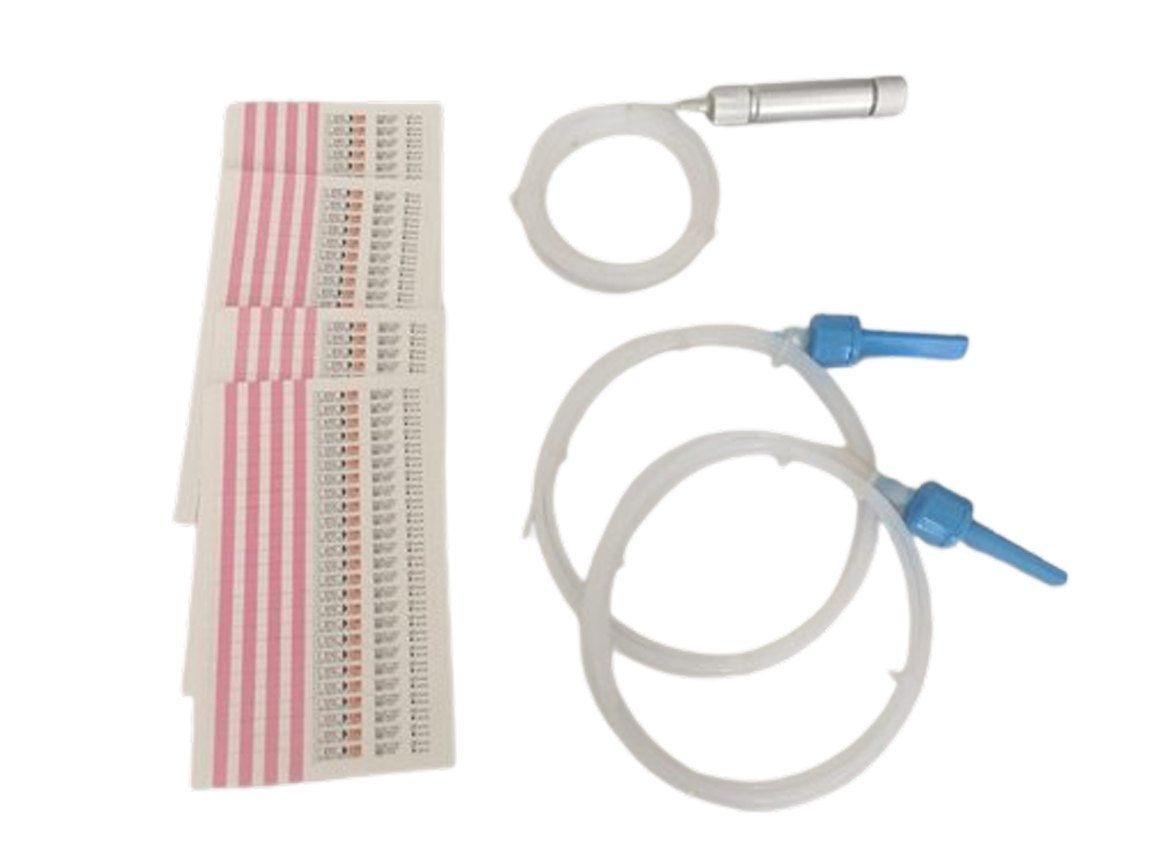

Process challenge devices are mainly differentiated by the way in which they indicate a successful sterilization process, and all PCDs have at least one type of indicator that signals to technicians whether or not sterilization has occurred.

These indicators are:

- Biological indicator — A test system that contains live bacterial contaminants (most commonly Geobacillus stearothermophilus spores) chosen due to their high resistance to steam and vaporized hydrogen peroxide.

- Chemical indicator — Once exposed to a sterilizing agent, a chemical indicator will react and undergo a physical change (typically a color change) that shows technicians whether or not the agent was satisfactorily present during the test cycle. Used to monitor the presence of the agent only.

- Enzyme indicator — This type of indicator contains enzymes taken from bacterial spores, and are used as part of rapid-read PCDs. Though not technically biological, enzyme indicators are most commonly used to test sterilizers that would typically rely on biological indicators to determine performance.

It’s important to note that the type of indicator used largely depends on the type of sterilization process the PCD is meant to validate. For example, biological and chemical indicators are widely used for steam and vaporized hydrogen peroxide sterilization tests.

How Do Process Challenge Devices Work?

For autoclaves, PCDs include both chemical and biological indicators. The chemical indicator is sensitive to steam, and reacts when exposed to it. The biological indicator, on the other hand, must be inactivated (killed or otherwise made inactive) in order to validate successful sterilization.

The only way for an autoclave to beat a validation test is if both indicators show a definitive pass response. More specifically, the chemical indicator must demonstrate that steam penetrated the test pack, while all contaminants within the biological indicator must also be completely destroyed. On its own, the chemical indicator is not enough to prove sterilization, as it is only able to detect whether or not steam was present during a validation cycle. The biological indicator is what determines the effectiveness of an autoclave’s ability to kill contaminants.

For a different perspective, try thinking about a successful validation test from the perspective of baking a cake. The chemical indicator will only tell you that your oven is on, while the biological indicator communicates that, not only is the oven on, but you’ve set it to the right temperature and programmed the timer for long enough to produce a perfectly baked final product.

Once the test cycle is complete, the biological indicator undergoes an incubation period, during which technicians will observe any spore growth. If propagation occurs, it means that sterilization has failed. A successful cycle will prevent spore growth from occurring at all.

Process Challenge Devices & Validation

At its core, the validation process is a test of a sterilizer’s performance. PCDs are essential to this process because they’re the tool that proves sterilization efficacy. For validation cycles, multiple PCDs are strategically placed throughout the chamber to ensure the most accurate readings, with a successful result occurring when all devices confirm that effective sterilization has been achieved.

However, when it comes to the nitty gritty details of what this process entails and how often it must be performed, there are no set requirements as it differs based on setting. For example, in healthcare environments, the CDC recommends verification of sterilization upon installation, relocation, or redesign of a unit; or after major repairs or sterilization failure.

FAQs

Q: What is a process challenge device (PCD)?

A: A process challenge device is a tool used in laboratories and healthcare facilities that determines the efficacy of the sterilization processes. These devices are specifically designed to simulate highly complicated loads and are placed within sterilizing units during validation testing to challenge their efficacy.

Q: What types of PCDs are there?

A: Process challenge devices are differentiated by the type of indicator they use. There are three major indicator types: biological, chemical, and enzyme. Biological indicators contain live bacterial contaminants chosen because of their high resistance to certain sterilizing agents, chemical indicators monitor the presence of a sterilizing agent, and enzyme indicators contain enzymes taken from bacterial spores and are used as part of rapid-read PCDs.

Q: Can PCDs be reused?

A: PCDs are designed for one-time use and cannot be reused.

Q: How often should validation occur?

A: Validation frequency varies depending on the setting. In healthcare facilities, for example, it’s recommended that sterilizers undergo validation cycles upon installation, relocation, or redesign of a unit; or after major repairs or sterilization failure.

Validation & Your Autoclaves

Validation is a crucial part of ensuring your autoclave lineup stays online and your sterilization standards remain in line with regulatory requirements. Download your copy of our free eBook: “How to Validate an Autoclave” for more about the tests you may need to perform in order to properly and effectively validate your sterilizers.

Or get in touch with our team of autoclave experts to start the conversation about your validation needs.